| Introduction | Historical Background | Chronology | Geography | Biography | Technology | Ownership and Financing | General Bibliography |

| Technology | Earthen Pipe |

Earthen pipes, also known as clay or stone ware, were usually made by potters and could be glazed or unglazed. They were used in Roman waterworks and also in some English works, such as Portsmouth in 1595. Earthen conduits were mentioned by Dr. Joseph Browne in a 1799 letter, and many companies produced them in the early Nineteenth Century. Terra cotta water pipes were used after the Civil War.

Michael Freytag and John Curtis proposed to make earthenware pipes for the new Philadelphia water works in 1801, but "no one believed in them." Freytag and Curtis were potters in Philadelphia, see 1980 reference.

Jesse Kersey, Chester County, PA 1820, used in Reading, Pennsylvania

Vickers and Valentine, Reading, PA 1822

Joseph Putnam Stone ware pipe, Salem, MA 1827

The Southern Porcelain Company - Kaolin, South Carolina, 1856

Kaolin Company, Augusta, Georgia 1857

|

| California Farmer and Journal of Useful Sciences 9(21):165 (June 11, 1868) |

A few water works systems used earthen pipes, but they were universally unsuccessful and replaced with other materials.

Farmington, Connecticut, date unknown.

Troy New York 1812 Earthen Conduit Company of Troy

Washington DC 1826 Bakewell

Kennett Square, PA 1842 Terra Cotta

Chicopee MA Vitified pipe

Augusta GA, Kaolin pipe

Sacramento CA 1858

Auburn CA 1858

Marysville CA 1858

Suisun City CA 1858

Hazleton, PA about 1860, Terra Cotta

Honesdale, PA 1863 Terra Cotta

Haverhill, MA 1864 earthen pipe

White Haven, PA, about 1870, Terra cotta

Saint Paul, MN 1870

Brookline, MA 1875

Richfield Springs, NY 1879. Ten-inch earthenware pipe one-half mile long.

Westminster MD 1883

Atlantic City NJ 1883

References

1805 Samuel Bartlett, patent #637X, October 1, 1805 for Pipes of

clay, conduit, Hartford, Connecticut. Another patent #987X, January

5, 1809 for conduit, clay, Hartford, Connecticut. Sales agent for

Connecticut (except Windsor County), - Nathaniel Seymour, West Hartford,

1807. Pipes may have been used in Farmington, Connecticut.

1806 "Conduit, Samuel Bartlett," Connecticut Courant, February 26, 1806, Page 2.

1806 Samuel Bakewell, 1806, no patent, widely advertised and used in Washington, D. C.

1808 Robert Ramsey, patent #893X, June 24, 1808 for pipes, conduit, mode of making from clay, Hanover, New Hampshire.

1807 "Nathaniel Seymour, of West-Hartford," American Mercury, February 19, 1807, Page 1.

1810 "Earthen

Aqueducts," New-England Palladium (Boston, Massachusetts),

January 9, 1810, Page 1.

Mr. Robert Ramsay, of Hanover, N.H. has invented a machine, with which he

moulds and presses clay pipes for Aqueducts. By the operation of

this machine pipes are moulder, and pressed so hard, that when property

burnt, they are nearly as solid and heavy as stone. The pipes are

about eighteen inches in length, and can be made to any dimensions,

necessary for common Aqueducts. They are made with such facility,

that the cost does not exceed wooden pipes. Their strength and

durability are incalculabe. If property burnt, they will last as

long as stone. The water conveyed in these earthen pipes, will not

be contaminated by them. This invention promises much. The

pipes are joined something in the manner of wooden Aqueduct pipes, and

fastened by a strong, cheap and durable cement.

1810 James Ramsey, patent #1258X, April 4, 1810 for Tubes, clay, for aqueduct, Burke, Vermont. Used at St. Johnsbury, Vermont, and Troy, New York

1811 "James Rumsey's Patent Machine for making earthen Aqueduct Pipes," Hartford Courant, October 2, 1811, Page 3.

1820 Village

Record (West Chester PA), March 8, 1820, page 3.

The Subscribers Inform, that they are now provided with a handsome stock

of EARTHEN PIPE For the conveyance of water underground. These pipes

are connected with a a durable cement, and are capable of sustaining a

considerable pressure. They have been proved in several different

places, and are preferred by all who have tried them. It is

presumed, that they will obtain a general preference, as their durability

is greater than can be expected from bored logs; and the water passing

through them is more pure. We might refer the public to a number of

persons who have tried them, but we need that unnecessary.

They also continue the Earthenware business, on a scale sufficient

extensive to afford a liberal supply to Store keepers. All orders

sent by mail to the Downington post office, will be promptly attended to;

and ware of the first quality delivered.

JESSE KERSEY, & Co. 2d month 29, 1820

1826 John Bower, Patent #4,591X, Mode of making clay pipes, East Bethlehem, Pennsylvania, December 1, 1826

1827 Joseph Putnam, Patent #4,640X, Mode of making pipes, tubes, etc., Salem, Massachusetts, January 17, 1827.

1828 Thomas Wickersham, making clay pipes, Patent #5,110X, Newbury, York County, Pennsylvania, May 13, 1828.

1851 "Stone Water Pipes," The Cincinnati Enquirer, November 19, 1851, Page 1.

1857 "Earthen

Water Pipes," Oroville Daily Butte Record (Oroville,

California), October 10, 1857, Page 2.

The Age says that earthen water pipes of a very superior quality, are

being made at the Brannan Pottery, near Sutter's Fort. They are

vastly cheaper than iron pipe, and just as serviceable once put in their

places.

1858 "Potteries,"

Sacramento Daily Union, January 1, 1858, Page 2.

The Sacramento Pottery, (S.C. Bruce, proprietor) located near the Fort,

has discontinued the manufacture, except as to earthen pipe, which is

conducted with machinery. The pipe, which is of superior quality,

and in demand for irrigation purposes, is constructed of all sizes, from

1¼ to 4 inch diameter, and with singular facility. The same

machinery is capable of manufacturing the hollow or tubular brick, and has

turned out a small lot for the San Francisco market. It is

contemplated to erect a steam engine in the spring, and to conduct the

manufacture with steam power on an extensive scale.

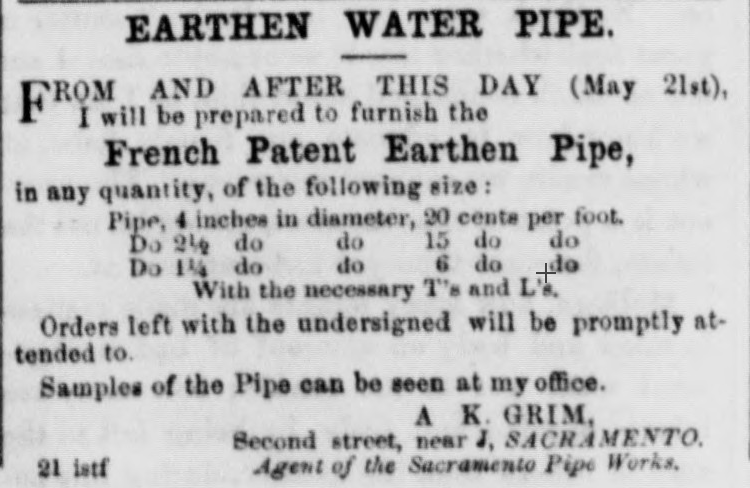

1858 "Earthen

Water Pipe," California Farmer and Journal of Useful Sciences

10(2):165 (August 13, 1868)

This kind of pipe is now becoming known, and quite extensively used, to

convey water under ground. So far as heard from, it has given perfect

satisfaction, and been found to answer the purpose admirably. The cost of

the pipe makes it the cheapest and best pipe used; and being made by

machinery of the most perfect construction, it will make handsome joints

and finished work. About one mile of this pipe has been used in Suisun

City. It is also used extensively in Sacramento. About 1500 feet was

purchased for Auburn. The Stockton Asylum use it extensively to convey

water. Maj. Hensley, of San Jose, has engaged 4000 feet for water piping,

and Judge Bliss, of Marysvillc, about 1500 feet. These are some instances

of its use; and from the testimony received from various sources, the

public can rest assured it is worthy their attention. We learn that the

company who manufacture this pipe, and whose advertisement appears in our

columns, will have samples, of various sizes, as well as their new fluted

brick, on exhibition at the State Fair, and also at the Mechanics' Fair.

A. K. Grim. Esq., of Sacramento, is the agent of the company, and will

furnish every information requisite.

1860 Weekly

Miners' Journal (Pottsville, Pennsylvania), April 21, 1860,

Page 3.

Terra-Cotta Pipe Agency! Stone Pipes, for conveying water to

colleries or dwellings, and as discharge pipes for carrying water

off. The subscribers have on hand, and are prepared to furnish stone

pipes from 2 to 12 inches in diameter--with elbows and connections for

connecting at any angle.

1860 "Home

Industry - Southern Porcelain Company," Georgia Weekly Telegraph,

October 4, 1860, Page 6.

The company are also manufacturing porcelain water pipes, and have now

contracts on hand for $50,000 worth of those, a large portion of which is

for the water-works of the city of Augusta.

1884 History

of Philadelphia, 1609-1884, Volume 1, by John Thomas Scharf

and Thompson Westcott

Page 510: 1801. Michael Freytag and John Curtis proposed to make

earthenware pipes, but no one believed in them.

1887 "Earthen-Ware pipes," by A. H. Howland, The American Engineer 13:156 (May 4, 1887)

1888 "The Use of Salt Glazed Vitrified Pipe in Water-Works Conduits," by Stephen E. Babcock, C.E., Proceedings of the Annual Conference of the American Water Works Association 9:29-46 (April 1888) Also includes information on wood stave conduits.

1888 "The Use of Salt Glazed Vitrified Pipe in Water-Works Conduits," by Stephen E. Babcock, C.E., Engineering News 19:331-333 (April 28, 1888)

1896 "Tests of the Tightness of a Vitrified Earthenware Water Conduit," by Dabney, H. Maury, Jr., Superintendent, Period Water Co., Engineering News 35:341-342 (May 21, 1896)

1980 Handcraft

to Industry: Philadelphia Ceramics in the First Half of the Nineteenth

Century by Susan H. Myers

Page 38: John Brelsford was a potter by 1846 and by 1849 he had

established the "Northern Liberties Stone Ware Manufactory" at New Market

and Germantown Road. In 1853 he advertised that he made water pipes,

chemical stoneware, and general household ware.

Page 49: Note 31. South Fifth between Cedar and Shippen: Michael Freytag,

by 1794-1807; Daniel Freytag, 1808-1824.

Page 55: Brelsford, John 1846-1858. Potter at New Market and Germantown

Road between 1846 and 1857. He may have operated his own pottery during

all of this 12-year period although he listed himself only as "potter"

until 1849 when he advertised his "Northern Liberties Stone Ware

Manufactory . . . orders received at John Eckstein's, 36 n 3d st,

Cornelius & Son, 176 Chesnut st." In the same year he listed the

"Northern Earthenware Factory" but there is no indication that he

continued to make earthenware. Brelsford is included in the 1850 census of

manufactures (MC 3; see Appendix II). In 1853 the directory indicates that

he was "manufr. of Chemical Apparatus, Stone Water Pipes, and Stoneware in

general." (PD 63-65, 68-74, 76, 78-82, 84, 88.) Two examples of his

household stoneware are illustrated in Figures 26 and 27.

Page 57: Curtis, John 1797-1831? From 1797 through 1804 John Curtis,

presumably the son of the above mentioned John Curtis, was a potter at 405

South Front Street. Apparently expanding the pottery, his address included

407 as well as 405 South Front between 1805 and 1822. He is listed at 405,

407, and/or 409 South Front Street as late as 1831 but is not listed as a

potter after 1824.

Page 59: Freytag, Daniel 1806-1824. Probably the son of Michael Freytag,

Daniel Freytag was a potter at 409 North Front Street in 1806 and 1807 and

by 1808 was at the family pottery on South Fifth Street between Cedar and

Shippen. When Michael Freytag changed his occupation to Justice of the

Peace in 1808 he apparently retired from the potting business, turning the

operation over to Daniel. (PD 19-21)

In 1810, Charles Dasher, an apprentice under Michael Freytag since 1805,

was rebound to Daniel Freytag. By 1811 Daniel Freytag was making fine ware

and was given special mention in the "Census" city directory.

Page 60: Freytag, Michael By 1794-1807 Potter at South Fifth Street

between Cedar and Shippen from 1794 to 1807. In 1808 he gave up potting

and became "justice of the peace," maintaining his address in the same

block as the pottery. (PD 4, 8-10, 12, 15-21.) Michael Freytag's pottery

is undoubtedly the one referred to in the following 1797 advertisement:

Earthen Ware Manufactory.—Cheap Iron Kettles. For Sale, Three large

cast-iron Kettles or Boilers, generally used for boiling sugar in the

West-Indies, and post askes, [sic] etc. in this country. Apply at the

Earthen Ware Manufactory, in Fifth below South street.

Page 105: Note 6. 6. For convenience of definition, ceramic bodies

generally are divided into three major types—earthenware, stoneware, and

porcelain—essentially determined by the composition of the clay, the

porosity and density of the finished product, and the temperature to which

each must be fired relative to the type of clay used and the end result

desired. The first, earthenware, is fired to the lowest temperature,

generally is porous, and consequently requires a glaze if it is to be

watertight. It ranges in color between buff and red and can be made very

light in color by the addition of a light-burning clay. Stoneware has a

higher firing point than earthenware, is buff, grey, or brown in color,

and requires no glaze to be watertight, though it usually is glazed for

general utility and appearance. Stoneware is highly vitrified but not

translucent as is porcelain. Porcelain has a vitrified and translucent

body and usually is white in color. Authorities differ on the precise

distinction in firing range between the three types but there is general

agreement on the approximate figures of below 1200°C for earthenware,

between 1200°C and 1400°C for stoneware, and roughly 1300°C and above for

porcelain.

Also see the general bibliography page, which includes links to several

lists of waterworks with information about pipes.

© 2016 Morris A. Pierce